Top Hoodie Manufacturer Guide: How Premium Hoodies Are Made in 2025

(Complete Production Process + OEM Factory Advantages)

Table of Contents

- What Defines a Premium Hoodie in 2025?

- Step-by-Step Hoodie Manufacturing Process

- Premium Hoodie Materials in 2025

- Printing & Embroidery Techniques

- Quality Control Standards

- Why Choose a Chinese OEM Hoodie Manufacturer

- Conclusion

What Defines a Premium Hoodie in 2025?

Premium hoodies in 2025 are built on higher expectations of fabric quality, durability, sustainability, and detailed craftsmanship.

Brands, especially in streetwear, athleisure, and luxury apparel, now require:

- Heavyweight 430–550gsm fabrics

- Soft-touch, skin-friendly finishing

- Improved shape retention

- High-density stitching & reinforced seams

- Eco-friendly production workflows

As competition grows, manufacturers must meet stricter quality and consistency standards.

Step-by-Step Hoodie Manufacturing Process

A premium hoodie goes through a complete, technical manufacturing chain. Below is the modern 2025 process used by professional OEM factories.

1. Fabric Inspection & Preparation

All fabrics are inspected for:

- GSM accuracy

- Color consistency

- Stretch & strength

- Shrinkage rate

- Surface defects

Only fabrics that meet brand specifications enter production.

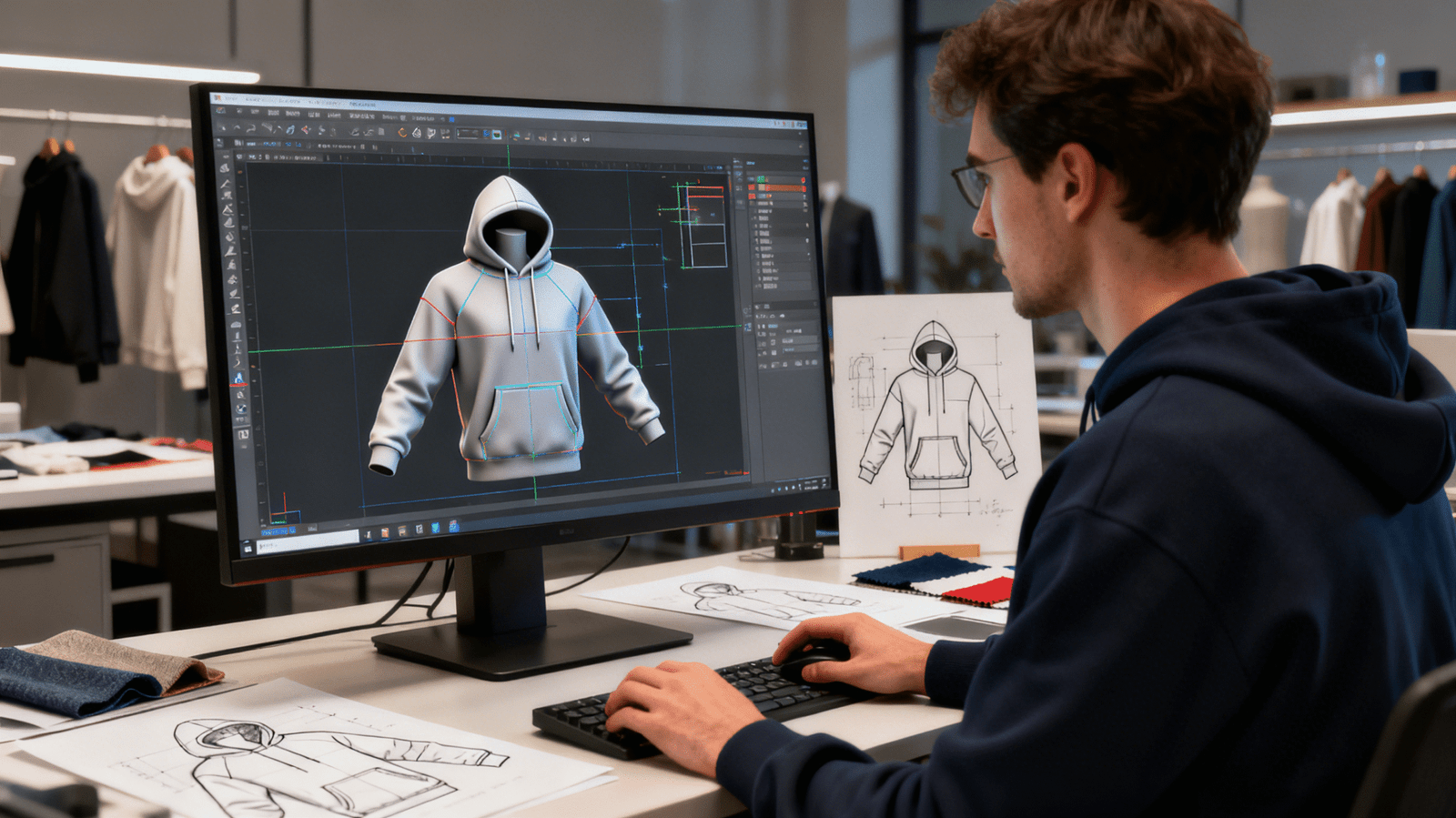

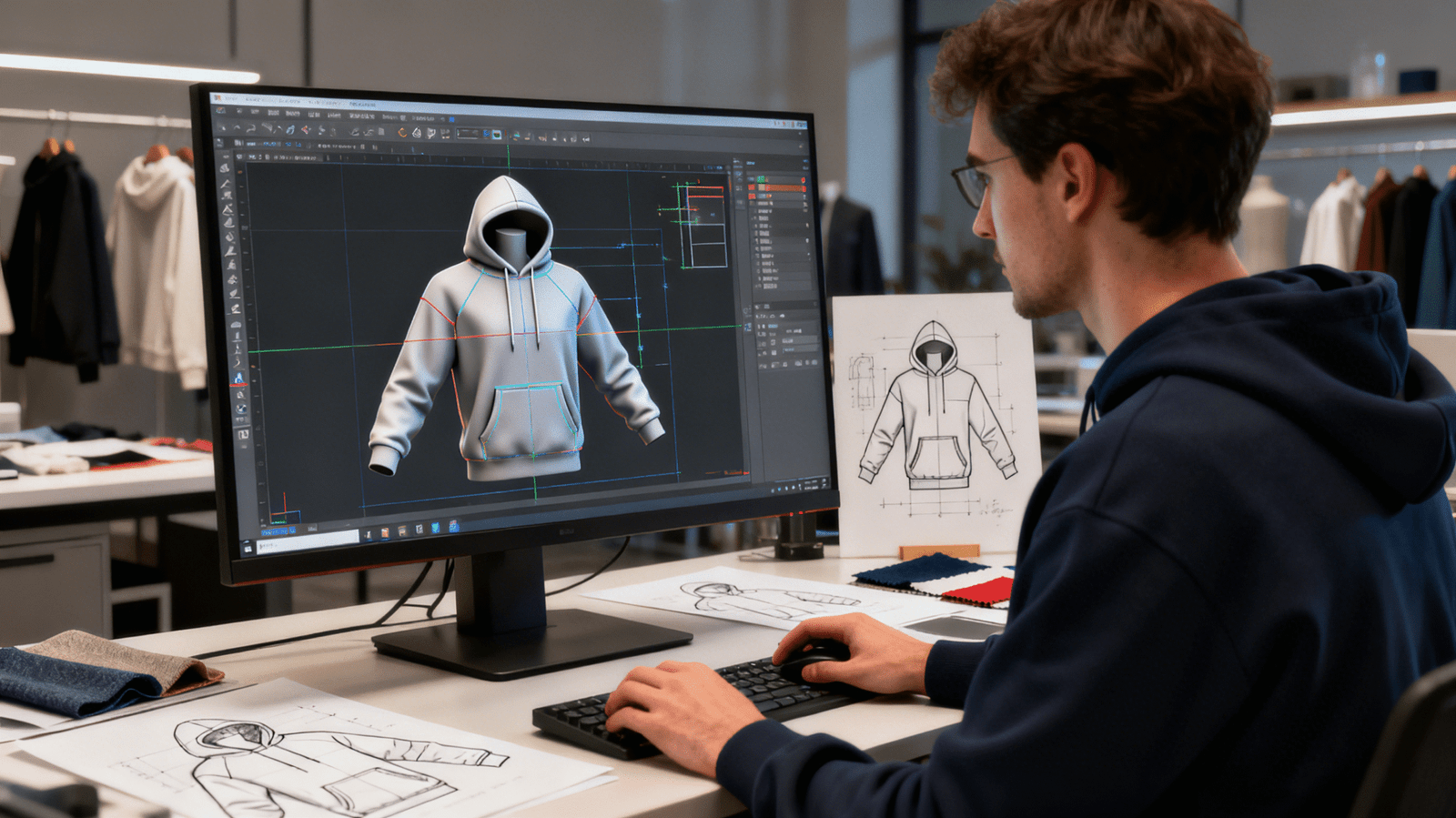

2. Pattern Making & 3D Grading

Factories now use 3D pattern systems to ensure better fit, improved comfort, and fewer production errors.

3. Automatic Fabric Cutting

High-precision auto-cutting machines ensure symmetrical panels and reduce material waste.

4. Sewing & Construction

Premium hoodie sewing includes:

- Shoulder reinforcement

- Kangaroo pocket bar-tacking

- Twin-needle stitching

- 4-needle 6-thread seams

- Reinforced hood construction

These techniques increase durability and premium feel.

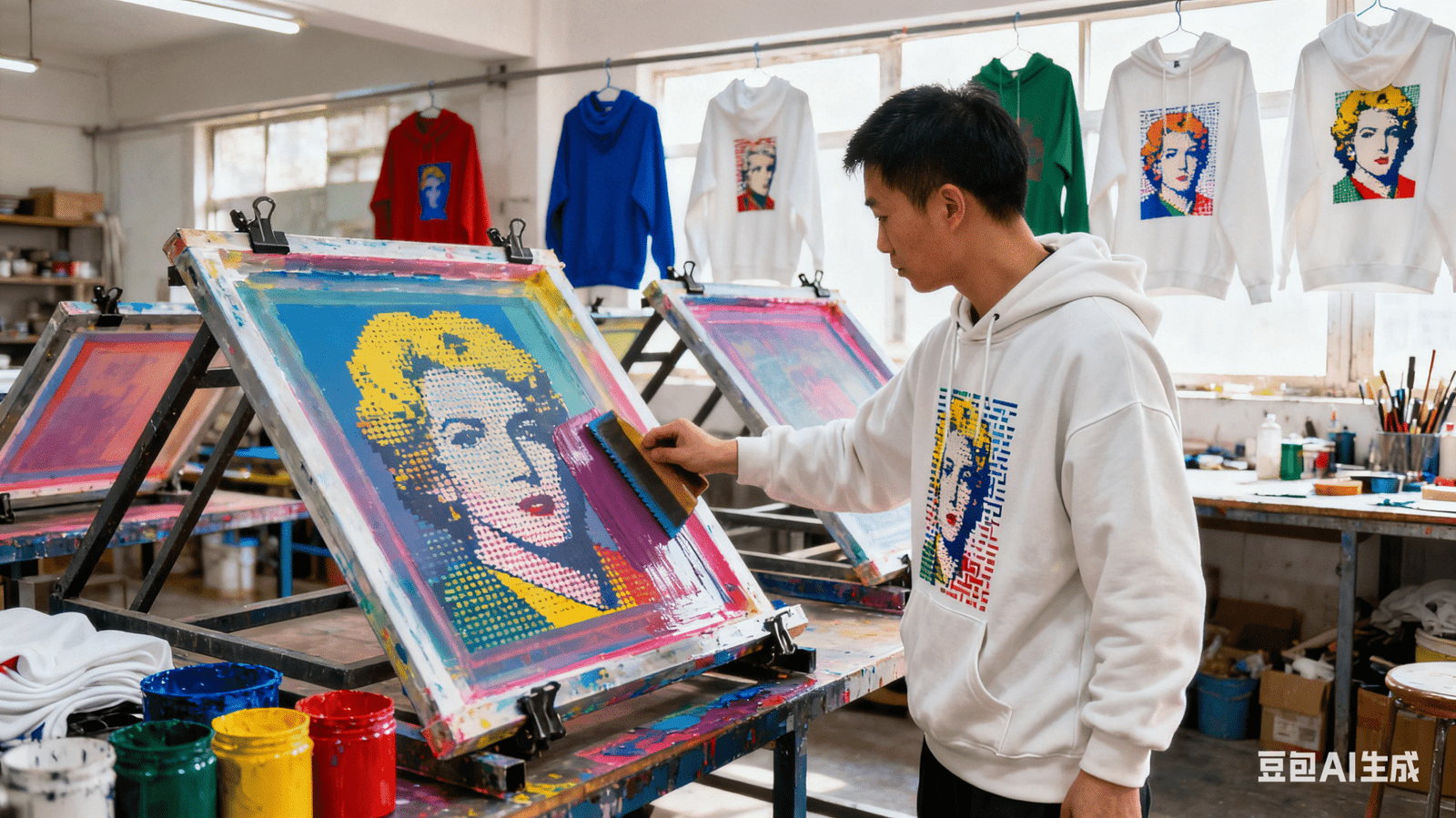

Popular 2025 techniques include:

- Puff print (3D print)

- Screen printing

- DTG digital printing

- Silicone rubber patches

- Heavy embroidery, beadwork, chain embroidery

Streetwear and luxury brands rely heavily on unique graphic execution.

6. Washing & Finishing

Factories provide special finishes like:

- Acid wash

- Enzyme wash

- Pre-shrunk finishing

- Soft-touch treatment

- 3D mold shaping

These ensure stable sizing and premium texture.

7. Final Quality Control

QC steps include:

- Measuring all sizes

- Checking stitch tension

- Artwork alignment

- Color consistency

- Ironing & packaging inspection

Strict QC ensures brand-level consistency.

Premium Hoodie Materials in 2025

1. 100% Heavyweight Cotton

430–550gsm for streetwear and premium luxury collections.

2. French Terry

Soft, breathable, ideal for sportswear.

3. Cotton Fleece

Warm and smooth, best for fall/winter lines.

4. Organic or Recycled Cotton

Eco-friendly and meets EU/US sustainability certification.

Printing & Embroidery Techniques

Factories offer:

- High-solidity screen prints

- Water-based prints

- DTG color gradients

- Flock printing

- Embossed silicone patches

- Embroidery + appliqué combinations

These enhance branding and retail appeal.

Quality Control Standards

Premium hoodie manufacturers follow:

- AQL 1.5–2.5 inspection

- Colorfastness tests

- Stretch & recovery tests

- Print durability tests

- Fabric pilling resistance

- Shrinkage control

Brands prefer suppliers who can guarantee repeatable quality for reorders.

Why Choose a Chinese OEM Hoodie Manufacturer?

China remains the leading destination for global hoodie production because:

1. Advanced machinery & automation

Improved accuracy and lower labor cost per unit.

2. Complete supply chain

Fabric mills, printing factories, and sewing lines are all integrated.

3. Flexible MOQs

Suitable for small brands and mass retailers.

4. Strong customization capabilities

Logos, patches, heavy embroidery, acid wash, oversized patterns — all in one place.

5. Faster production timelines

Shorter sampling and bulk delivery compared to other regions.

Conclusion

Premium hoodie production in 2025 blends advanced technology, skilled craftsmanship, sustainable materials, and strict QC systems.

Brands that partner with a professional OEM hoodie manufacturer gain access to:

- Better control of product quality

- Wider customization options

- Faster turnaround

- More competitive pricing

This is why top streetwear, sportswear, and high-end fashion brands continue choosing OEM manufacturers for hoodie development.

A skilled manufacturer ensures:

- Stable quality

- Accurate sizing

- Shorter lead times

- Lower defect rates

- More printing/embroidery options

- Customization for brand identity

This helps brands launch best-selling T-shirts faster and enter the market with confidence.

🔖 Tags (SEO Optimized)

t-shirt manufacturer, custom t-shirts, t-shirt production process, t-shirt printing, screen printing t-shirt, dtg t-shirts, puff print t-shirt, wholesale t-shirts, t-shirt factory china, cotton t-shirts, apparel manufacturer, private label t-shirts, custom logo t-shirts, bulk t-shirt supplier

📌 Meta Description (SEO)

High-quality guide explaining how T-shirts are made, including fabrics, cutting, sewing, printing, and packaging. Ideal for brands, startups, and wholesale buyers looking for reliable T-shirt manufacturing.

📌 Canonical URL

<link rel="canonical" href="https://yourdomain.com/t-shirt-manufacturing-guide" />

📌 Open Graph / X (Twitter) Preview Tags

<title>T-Shirt Manufacturing Guide: How High-Quality T-Shirts Are Made</title>

<meta property="og:title" content="T-Shirt Manufacturing Guide">

<meta property="og:description" content="Learn how T-shirts are made—from fabrics to sewing, printing, and quality control. Perfect for brands and buyers.">

<meta property="og:image" content="https://yourdomain.com/og-image.jpg">

<meta property="og:url" content="https://yourdomain.com/t-shirt-manufacturing-guide">

<meta name="twitter:title" content="T-Shirt Manufacturing Guide">

<meta name="twitter:description" content="Full T-shirt production process explained.">

<meta name="twitter:image" content="https://yourdomain.com/x-image.jpg">- Textile Exchange – Sustainable Fabrics Guide

- Fashion United – Apparel Manufacturing Insights

- The Business of Fashion – Printing Technologies

- OEKO-TEX® Certified Materials

- Made-How: How Sweatshirts Are Made

Meta Description:

Discover the complete sweatshirt manufacturing process—from fabric selection to printing, embroidery, and final packaging. Learn how professional factories ensure quality and innovation in every design.

Canonical URL:

https://dechoreal.com/how-sweatshirts-are-made

https://dechoreal.com/customization-service/