When I first looked for a zip-up hoodie manufacturer, I felt overwhelmed—too many options, too little clarity. I didn’t want to waste money on the wrong partner.

The best zip up hoodie manufacturers combine technical precision, consistent quality, and flexible customization. Choosing the right one can make or break your clothing business.

I’ve learned that asking the right questions leads to the right suppliers. In this guide, I’ll walk you through everything I wish I had known earlier. If you’re sourcing for your brand, keep reading.

Table of Contents

- What makes a good zip up hoodie manufacturer?

- What types of zippers are used in high-quality hoodies?

- How is a zip up hoodie made step by step?

- What customization options are available for zip up hoodies?

- Where to find reliable zip up hoodie manufacturers?

- Conclusion

What makes a good zip up hoodie manufacturer?

I once received a batch of hoodies with crooked zippers and fraying seams. That experience taught me what truly defines a reliable manufacturer.

A good zip up hoodie manufacturer ensures zipper durability, precise stitching, strong construction, and consistent materials across all pieces.

Key Qualities to Look for

| Feature | Why It Matters | What to Look For |

|---|---|---|

| Zipper Quality | Impacts user experience and durability | YKK or SBS with smooth operation |

| Construction Skill | Defines shape and structure | Proper cutting and panel alignment |

| Sewing Precision | Affects appearance and longevity | Tight, uniform stitches (e.g., 10-12 SPI) |

| Material Consistency | Ensures color and feel match | Use of certified fabrics (e.g., OEKO-TEX) |

| Production Capacity | Impacts lead time and fulfillment | Scalable factory with modern equipment |

| Communication Skills | Critical for customization and updates | Clear, responsive point of contact |

A quality manufacturer is also transparent. They share their MOQ (Minimum Order Quantity), pricing structure, sample timelines, and production capacity. If a factory dodges questions about quality checks or can’t show past work, that’s a red flag.

👉 For a deeper look into what defines a quality clothing factory, check this article by Maker’s Row.

What types of zippers are used in high-quality hoodies?

The wrong zipper can ruin the entire product. I’ve had hoodies returned by customers just because the zippers got stuck or broke after a few wears.

High-quality hoodies often use YKK or SBS zippers—both known for strength and smooth operation. Nylon and metal zippers serve different purposes based on design needs.

Comparing Zipper Types

| Zipper Type | Pros | Cons | Best Use |

|---|---|---|---|

| YKK | Reliable, global standard | Higher cost | Premium hoodies |

| SBS | Affordable, reliable | Less global recognition | Mid-tier products |

| Nylon Coil | Lightweight, flexible | May feel less premium | Casual styles |

| Metal | Durable, fashionable | Heavier, may tarnish | Streetwear or rugged looks |

| Invisible | Sleek appearance | Harder to repair | Fashion-focused items |

Zipper size also matters. #5 is most common for hoodies, but streetwear brands sometimes prefer #8 for a bolder look. Also consider the slider—autolock sliders prevent accidental openings and are standard in athletic wear.

👉 Learn more about zipper technology on YKK’s official website.

How is a zip up hoodie made step by step?

I used to think making a hoodie was simple. But after visiting a factory in Guangdong, I realized the process involves over 10 precise steps.

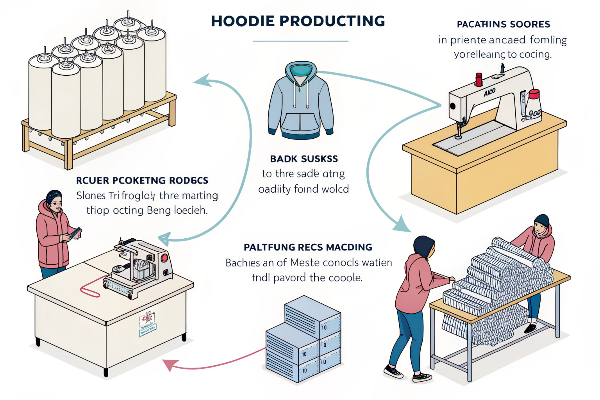

The manufacturing of a zip-up hoodie includes fabric sourcing, pattern making, cutting, sewing, zipper installation, washing, inspection, and packaging.

Step-by-Step Breakdown

-

Fabric Selection

Based on GSM, stretch, and purpose (e.g., fleece, French terry, interlock). Fabrics should be pre-tested for color fastness and shrinkage. -

Pattern Making & Grading

Designers convert sketches into technical patterns. Patterns are graded for all sizes before entering production. -

Fabric Cutting

Fabric layers are stacked on large cutting tables. Cutting is done using high-speed electric knives or laser cutters. -

Sewing & Assembly

Skilled workers stitch sleeves, hoods, and cuffs using flatlock, coverstitch, and overlock machines. Reinforcements are added at stress points. -

Zipper Installation

Zippers are aligned with millimeter precision. Special machines or operators attach them with a secure seam line. -

Pre-washing or Pre-shrinking

Garments are washed or heat-treated to avoid post-sale shrinkage and ensure fabric softness. -

Quality Control (QC)

A QC team checks zippers, seams, logos, and color matching. Some factories use 5-point or AQL inspection systems. -

Trimming & Finishing

Threads are trimmed, drawstrings added, and logo placements reviewed before final packing. -

Ironing or Steaming

Products are lightly steamed and pressed to maintain shape before packaging. -

Packaging

Folded, polybagged, hang-tagged, and boxed as per client specifications. Some brands request eco-friendly packaging.

👉 Want to see this process in action? Check out this behind-the-scenes video of hoodie production.

What customization options are available for zip up hoodies?

When I started my private label brand, I realized just how many ways a hoodie can be customized. It’s what makes your product stand out in a crowded market.

Custom options include printed or embroidered logos, lining fabrics, colored drawstrings, branded zipper pulls, and unique sleeve or chest labels.

Common Hoodie Customizations

| Element | Options | Impact |

|---|---|---|

| Logo | Screen print, embroidery, heat transfer | Brand visibility |

| Inner Lining | Cotton, mesh, fleece | Comfort and insulation |

| Drawstrings | Colored, tipped, rope style | Aesthetic appeal |

| Zippers | Custom colors, branded pulls | Brand identity |

| Labels | Woven neck labels, sleeve patches | Perceived value |

| Pockets | Kangaroo, zippered, hidden | Functionality & style |

| Cuffs & Waistband | Ribbed, spandex blend | Fit and durability |

For fitness brands, moisture-wicking linings or ventilation holes can offer added performance. For fashion-forward clients, tonal embroidery and hidden zippered pockets are trendy choices. I once added sleeve embroidery to match my brand’s identity colors—it instantly improved customer feedback.

👉 Explore hoodie customization inspiration on Behance Apparel Design Projects.

Where to find reliable zip up hoodie manufacturers?

I’ve worked with over a dozen suppliers—and wasted thousands—before finding my reliable partners. Sourcing is both science and intuition.

Reliable manufacturers can be found through Google search, Alibaba, trade shows, and peer referrals. Vet them through samples, factory audits, and consistent communication.

Best Sourcing Channels

| Channel | Pros | Cons |

|---|---|---|

| Google Search | Direct websites, SEO-optimized companies | Hard to verify claims |

| Alibaba | Variety, ratings, easy contact | Risk of middlemen or low quality |

| Trade Shows (e.g., Canton Fair) | Face-to-face meetings | Travel required |

| Industry Forums/Groups | Real referrals | Not always up-to-date |

| Direct access to factory managers | Takes time to filter connections |

How to Vet a Manufacturer

- Request Samples: Test quality, materials, and print accuracy.

- Do a Virtual Tour or Video Call: Observe their facility and professionalism.

- Check Certifications: Look for ISO, WRAP, BSCI, OEKO-TEX for fabric and safety standards.

- Ask for Past Clients or Case Studies: It gives you social proof.

- Start with a Trial Order: Before committing to a bulk order, test communication and consistency.

I met one of my best manufacturing partners at a virtual sourcing show. Their follow-up was fast, sample turnaround was 5 days, and they offered clear tech pack templates. That's how I knew they took their craft seriously.

👉 Looking for a trustworthy partner? Check out Decheng's OEM/ODM Services for customized zip-up hoodie solutions.

Conclusion

Choosing the right hoodie manufacturer means combining quality, customization, and reliability—it’s a long-term relationship, not a one-time transaction.