Best Custom Pants Manufacturer Guide: How to Create High-Quality Joggers & Cargo Pants in 2025

A good pair of pants can define a brand, and in 2025, joggers and cargo pants are still among the strongest sellers. This guide explains how to work with a reliable custom pants manufacturer and create high-quality products that match today’s streetwear and activewear standards.

🧵 Table of Contents

- Understanding the 2025 Pants Market

- Choosing the Right Pant Fabrics

- How OEM Pants Manufacturing Works

- Joggers Production Process

- Cargo Pants Production Process

- Quality Control for Custom Pants

- Final Packaging & Shipping

- Conclusion

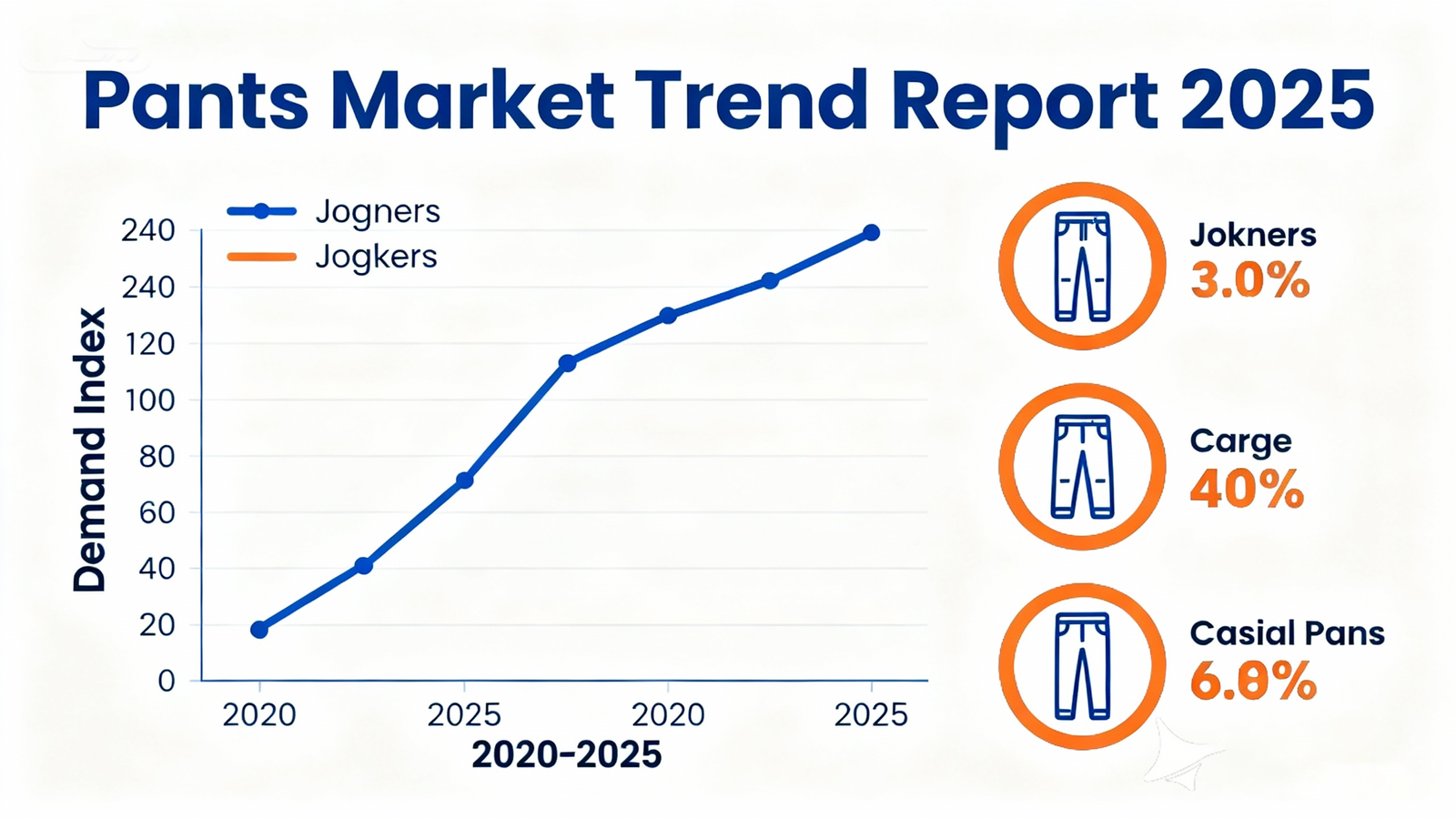

Understanding the 2025 Pants Market

Consumers continue to demand comfort, durability, and versatile styling. Joggers, utility cargo pants, and techwear pants dominate global searches, making them a strong choice for new and growing brands.

🖼️

Choosing the Right Pant Fabrics

The foundation of a high-quality pair of pants starts with the right fabric. Joggers require soft, flexible materials, while cargo pants need structure and durability.

Recommended Jogger Fabrics:

- 100% cotton fleece

- French terry

- Cotton-poly blends

- 4-way stretch performance fabrics

Recommended Cargo Pants Fabrics:

- Twill

- Heavy cotton canvas

- T400 stretch fabric

- Nylon techwear fabric

🖼️

How OEM Pants Manufacturing Works

OEM pants manufacturers help brands turn their ideas into finished products. The process typically includes:

- Tech pack review

- Material selection

- Pattern making

- Grading for all sizes

- Cutting

- Sewing

- Decoration (print / embroidery / patches)

- QC

- Packaging

This gives brands a full outsourced solution with consistent quality.

Joggers Production Process

High-quality joggers require clean stitching, perfect fit, and premium comfort.

Key Steps:

- Rib waistband selection

- String and accessories matching

- Panel sewing with cover-stitch

- Pocket construction

- Crotch reinforcement

- Final soft-wash or enzyme wash

🖼️  .

.

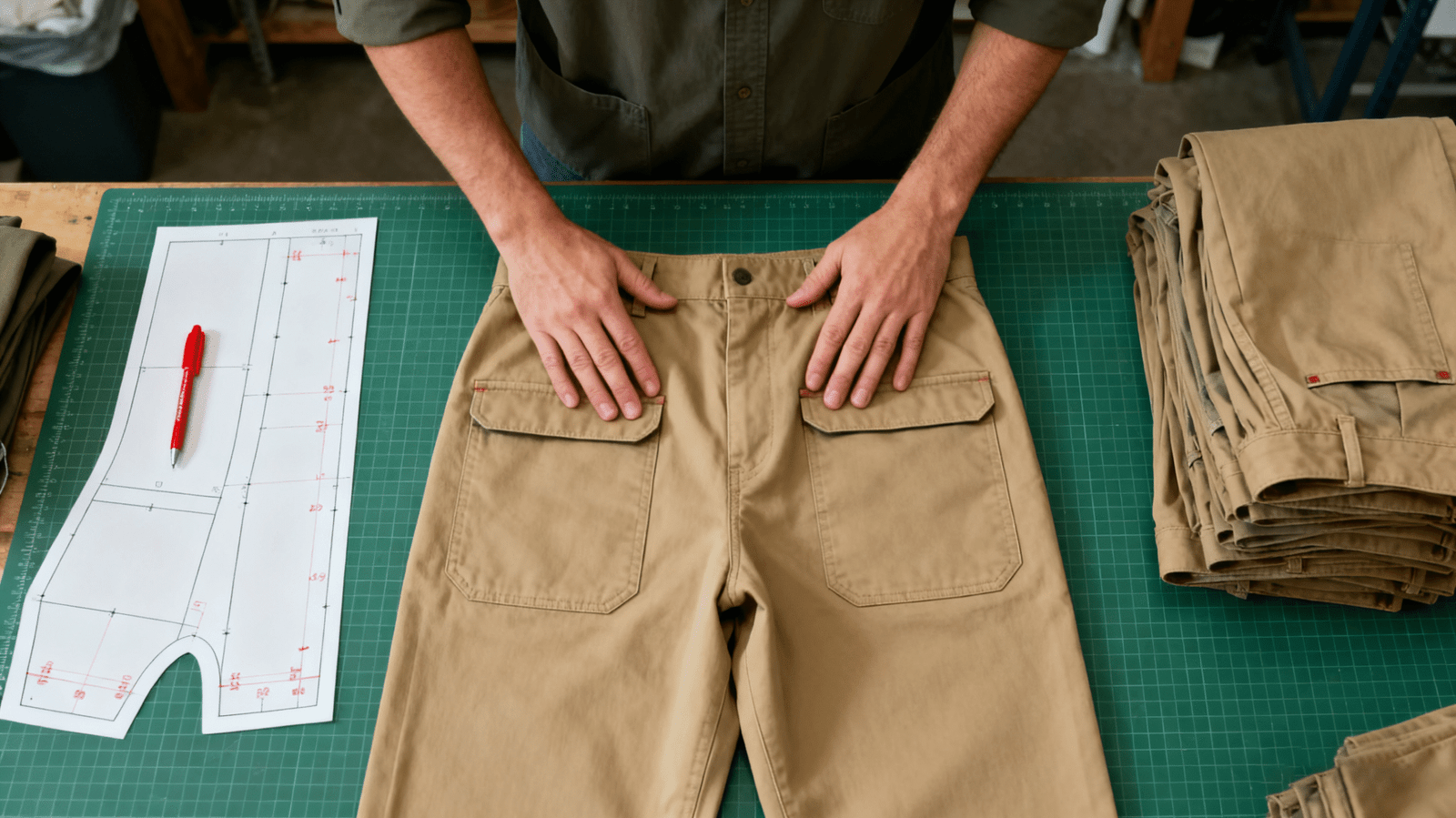

Cargo Pants Production Process

Cargo pants require more structure and detailed workmanship.

Key Steps:

- Cutting heavy twill or canvas

- Sewing multi-layer pockets

- Bartack reinforcement

- Knee panel construction

- Elastic or adjustable waist assembly

- Garment dye or wash process

🖼️

Quality Control for Custom Pants

QC ensures each pair meets brand standards.

Typical inspection points include:

- Measurement accuracy

- Stitch density & tension

- Pocket placement alignment

- Color consistency

- Print or embroidery quality

- Fabric defects

- Zipper and button durability

🖼️  .

.

Final Packaging & Shipping

Manufacturers usually offer:

- Custom packaging

- Brand labels & tags

- Polybag or biodegradable bag options

- Carton packing with size breakdown

- Export logistics and shipping assistance

This helps brands maintain a polished retail presence.

Conclusion

High-quality joggers and cargo pants require proper fabrics, clean construction, and a reliable OEM manufacturer. With the right partner, brands can scale faster and deliver consistent products in 2025 and beyond.

https://dechoreal.com/sportswear-manufacturer/