Full Guide: How to Start a Clothing Brand with an OEM Apparel Manufacturer

Starting a clothing brand is easier today, but competition is stronger than ever. Working with a reliable OEM apparel manufacturer can help you launch faster, reduce cost, and scale with confidence.

In this guide, I explain how to build a profitable clothing brand step-by-step, even if you are a beginner.

📌 Table of Contents

- Why Work with an OEM Clothing Manufacturer

- Choosing Fabrics for Your Brand

- Custom Printing & Embroidery Options

- Sampling Process Explained

- Bulk Production Workflow

- Quality Control & Packaging

- How to Scale Your Clothing Brand

1. Why Work with an OEM Clothing Manufacturer

An OEM apparel manufacturer allows you to create custom clothing without owning a factory. They handle fabric sourcing, cutting, printing, embroidery, sewing, and packaging — reducing your startup cost and risk.

📷 Image Placeholder w.

w.

2. Choosing Fabrics for Your Brand

Fabric determines quality, comfort, and price. High-end brands often choose 100% cotton, combed cotton, French terry, and fleece. Activewear brands prefer polyester-spandex blends for stretch and durability.

📷 Image Placeholder

Popular Fabric Choices

| Fabric Type | Best For | Features |

|---|---|---|

| 100% Cotton | Streetwear & basics | Soft, breathable, skin-friendly |

| French Terry | Hoodies & joggers | Smooth outside, loop inside |

| Fleece | Winter hoodies | Warm, thick, premium |

| Polyester-Spandex | Activewear | Stretchy, durable, moisture-wicking |

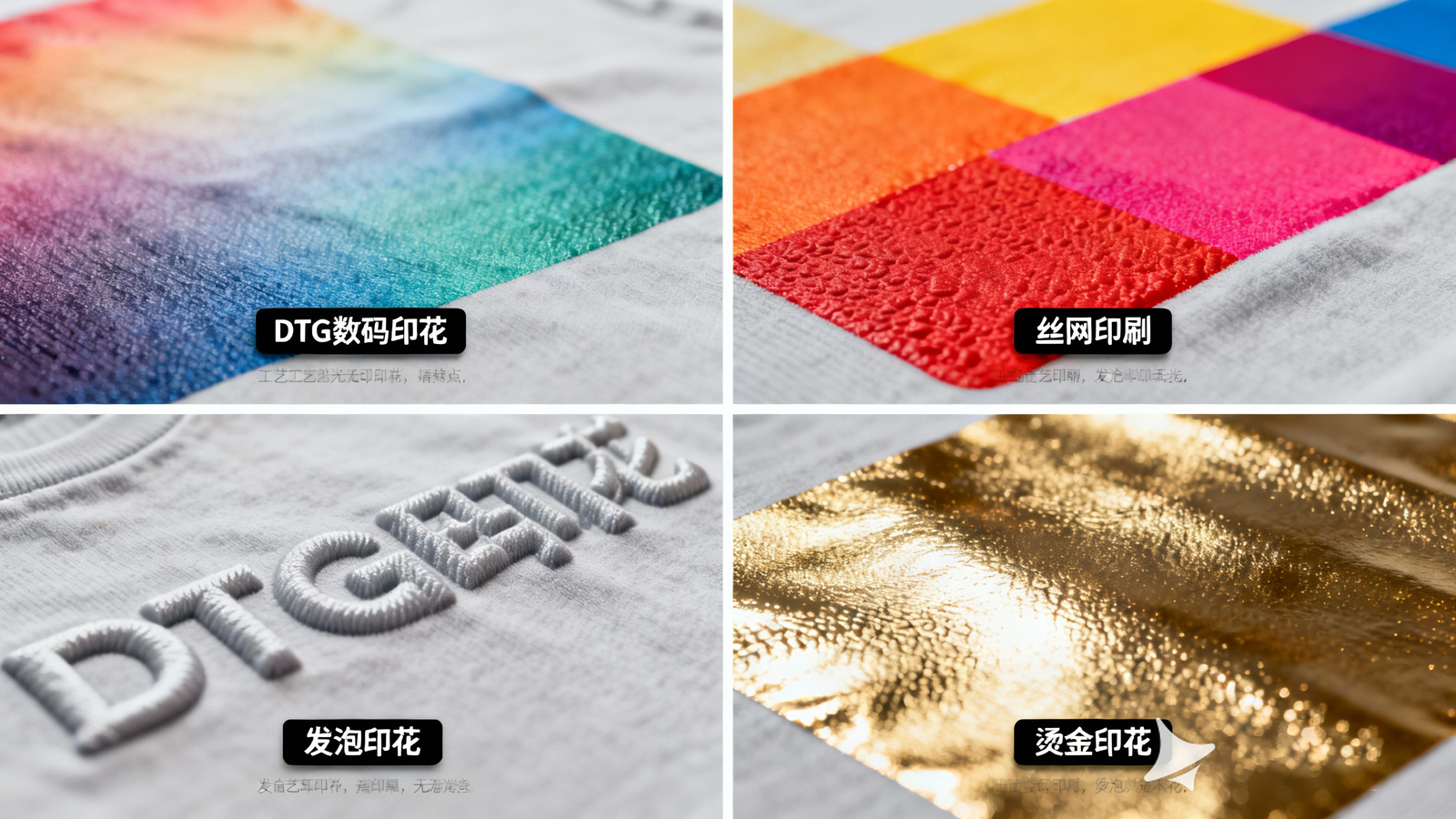

3. Custom Printing & Embroidery Options

Brand identity depends heavily on your decoration method. OEM factories can apply multiple techniques based on your design.

📷 Image Placeholder

Common Techniques

- Screen Printing – Best for bold colors, large orders

- DTG Printing – Best for detailed artwork

- Puff Print – 3D raised effect

- Embroidery – Luxury branding, logo stitching

- Chenille Patches – Streetwear signature style

4. Sampling Process Explained

Before mass production, OEM factories create a sample to confirm fabric, color, size, measurements, printing, and stitching quality.

📷 Image Placeholder

What You Approve in a Sample

- Fabric quality

- Color and pantone match

- Print/embroidery size and position

- Fit and measurements

- Stitching durability

5. Bulk Production Workflow

Once the sample is approved, production begins. The OEM manufacturer handles fabric cutting, sewing, printing, embroidery, QC inspection, and final packaging.

📷 Image Placeholder

Production Stages

- Fabric sourcing

- Cutting by machine

- Sewing

- Printing or embroidery

- Final inspection

- Packaging

6. Quality Control & Packaging

QC ensures your clothing meets your brand standard. This step checks stitching tension, print alignment, measurements, and fabric defects.

📷 Image Placeholder

What QC Checks

- Measurement accuracy

- Print alignment

- Stitch strength

- Fabric quality

- Packaging and labeling

7. How to Scale Your Clothing Brand

When your supplier is stable, you can focus on marketing, advertising, and building your product line.

How Brands Scale Quickly

- Add new styles each season

- Keep fabric and size consistency

- Invest in branding (tags, labels, packaging)

- Work with one reliable OEM manufacturer

- Use pre-orders to reduce risk

Conclusion

Working with a trusted OEM apparel manufacturer allows you to launch faster, control quality, and scale your clothing brand with confidence. It is the best starting point for beginners entering the fashion industry.