title: "How Sweatshirts Are Made: From Fabric to Finishing Techniques"

description: "Discover the complete sweatshirt manufacturing process—from fabric selection to printing, embroidery, and final packaging. Learn how professional factories ensure quality and innovation in every design."

canonical_url: "https://dechoreal.com/how-sweatshirts-are-made"

author: "DECHENG Garment Manufacturing"

date: "2025-11-06"

tags: ["sweatshirt manufacturer", "apparel production", "custom clothing", "OEM ODM", "fashion manufacturing"]

How Sweatshirts Are Made: From Fabric to Finishing Techniques

Table of Contents

- What Is a Sweatshirt?

- Step-by-Step Production Process

- Popular Fabric Options

- Printing and Embroidery Techniques

- Quality Control and Final Packaging

- Why Work With a Professional Manufacturer

1. What Is a Sweatshirt?

A sweatshirt is a comfortable, durable garment made from knitted fabrics. It comes in many styles—crewneck, hoodie, or zip-up—and is used for sportswear, streetwear, and fashion branding.

Alt text: various sweatshirt styles including hoodie, zip-up, and crewneck for unisex wear

2. Step-by-Step Production Process

Step 1: Fabric Selection

Manufacturing begins by choosing suitable fabrics—cotton, polyester, or blends. Each material affects comfort, texture, and durability.

Step 2: Pattern Making

Experienced pattern makers ensure each size maintains the correct proportions and fit.

Step 3: Cutting

Fabrics are layered and precision-cut using automatic machines for accuracy and efficiency.

Step 4: Sewing & Assembly

Skilled operators stitch all parts—body, sleeves, and ribs—using durable flatlock and overlock seams.

Alt text: skilled garment workers sewing sweatshirts on industrial sewing machines in China factory

Step 5: Decoration & Finishing

Sweatshirts are decorated with logos or artwork through different printing or embroidery techniques before pressing and packaging.

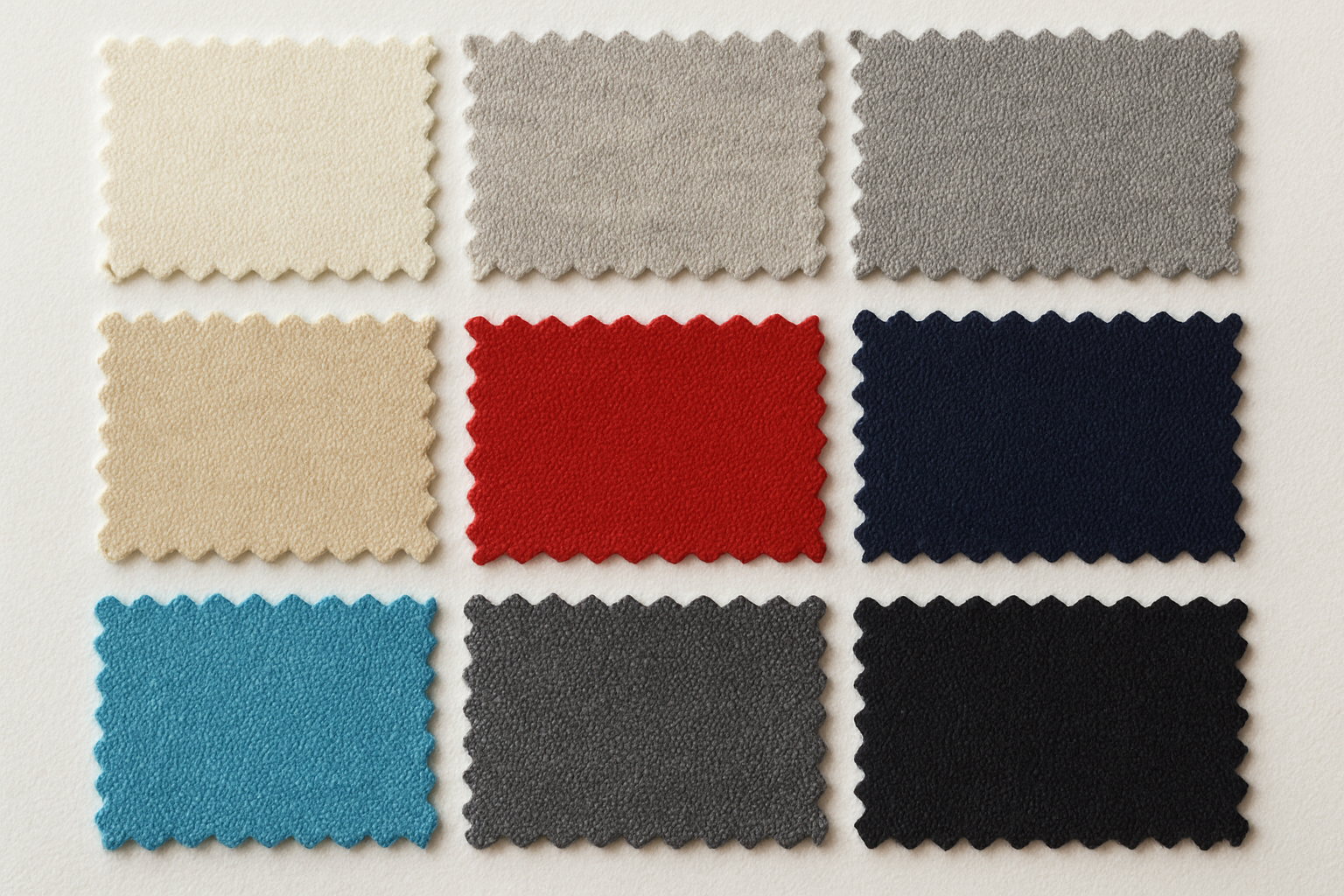

3. Popular Fabric Options

| Fabric Type | Key Features | Ideal Use |

|---|---|---|

| Cotton Fleece | Soft, breathable, natural | Premium casual wear |

| French Terry | Lightweight, looped inside | Gym or springwear |

| Poly-Cotton Blend | Less shrinkage, durable | Streetwear and uniforms |

| Recycled Fabric | Eco-friendly, sustainable | Green collections |

Alt text: cotton fleece, French terry, and blended sweatshirt fabrics in different textures

4. Printing and Embroidery Techniques

| Technique | Description | Style Effect |

|---|---|---|

| Screen Printing | Traditional ink layering | Bold, durable finish |

| Puff Printing | 3D heat expansion | Raised textured effect |

| Embroidery | Stitched logo or text | Premium, long-lasting |

| Digital Printing (DTG) | Inkjet on fabric | High-detail images |

| Chenille & Appliqué | Fabric patchwork | Luxurious varsity look |

!

Alt text: puff print, embroidery, and DTG examples on cotton sweatshirts

5. Quality Control and Final Packaging

Each sweatshirt is inspected for stitching quality, color accuracy, and print consistency. Approved garments are steamed, folded, labeled, and packed securely for export.

Alt text: folded sweatshirts packed in cartons with factory logo labels

6. Why Work With a Professional Manufacturer

Working with a professional sweatshirt manufacturer ensures:

- Access to certified fabrics and sustainable materials

- Skilled craftsmanship with modern machinery

- Fast OEM/ODM customization

- Consistent quality across large orders

External References

- Textile Exchange – Sustainable Fabrics Guide

- Fashion United – Apparel Manufacturing Insights

- The Business of Fashion – Printing Technologies

- OEKO-TEX® Certified Materials

- Made-How: How Sweatshirts Are Made

Meta Description:

Discover the complete sweatshirt manufacturing process—from fabric selection to printing, embroidery, and final packaging. Learn how professional factories ensure quality and innovation in every design.

Canonical URL:

https://dechoreal.com/how-sweatshirts-are-made